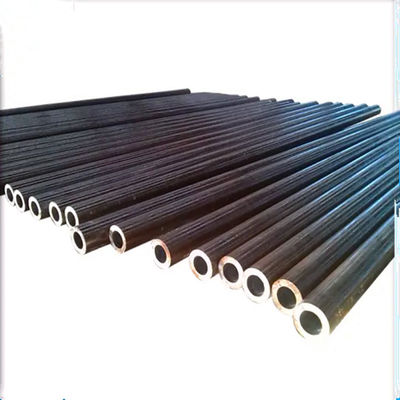

we carry a full inventory of Alloy Steel Seamless Pipe and Supply Alloy Steel Seamless Tube products in a variety of sizes to meet

the High temperature service requirements for applications the Power Plants, Petro Chmical Plants and Refineries industries. Alloy

Steel Seamless Pipes and Tube steel pipe can be structural in nature or used in fluid and oil transmission.

Laisser un message

Nous vous rappellerons bientôt!

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères!

Merci de consulter vos emails!

Merci de consulter vos emails!

SOUMETTRE

Plus d'informations facilitent une meilleure communication.

M.

- M.

- Mrs

D'accord

Soumis avec succès!

Nous vous rappellerons bientôt!

D'accord

Laisser un message

Nous vous rappellerons bientôt!

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères!

Merci de consulter vos emails!

Merci de consulter vos emails!

SOUMETTRE